Relief Valve Casting Shorud

Relief Valve Casting Shorud Specification

- Drawing

- Available as per clients requirement or supplied sample

- Micro Machining

- Available on request

- Standard

- ASTM, ANSI, IS (Based on requirement)

- Material Capabilities

- Corrosion Resistant, High Pressure Endurance

- Type

- Relief Valve Casting Shrouds

- Weight

- 1.5 kg 7 kg

- Material

- Stainless Steel, Cast Iron, Alloy Steel (Customizable)

- Tolerance

- 0.1 mm

- Finish

- Shot Blasted, Sand Blasted, or As Per Requirement

- Color

- Metallic Grey (Standard), Customizable

- Application

- Relief valve enclosures for industrial systems

- Dimension Range

- Customized as per drawing/specification

- Quality Testing

- 100% hydrostatic and visual inspection

- Surface Treatment

- Galvanized, Painted, or Natural Finish

- OEM Service

- Supported

- Pressure Class

- Class 150 to Class 600 (configurable)

- Process

- Precision Sand Casting / Investment Casting

- Port Size

- As per relief valve specification

Relief Valve Casting Shorud Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 2000 Pieces Per Month

- Delivery Time

- 20 Days

About Relief Valve Casting Shorud

Features & Applications of Relief Valve Casting Shroud

Our Relief Valve Casting Shroud stands out with its precise construction, corrosion resistance, and compatibility with a variety of relief valves. Designed for use by manufacturers and maintenance teams in industrial systems, it guarantees safety and operational efficiency. Suitable for general and specific industrial applications, this shroud is customizable in dimension, port size, and finish, ensuring a secure fit and premium protection for relief valve enclosures across multiple sectors.

Premium Delivery, Packaging, & Payment Details

Experience swift packing & dispatch with each premium Relief Valve Casting Shroud, carefully packaged to ensure damage-free delivery. Standard delivery timelines are discussed at order confirmation; expedited shipping is available on request. Flexible payment terms cater to client convenience, and sample units are readily provided for evaluation. Our commitment is to deliver a seamless, professional buying experience from initial inquiry through final installation.

FAQs of Relief Valve Casting Shorud:

Q: How can I select the appropriate Relief Valve Casting Shroud for my system?

A: Choosing the right shroud depends on your relief valve specifications, required pressure class, and application needs. Provide your drawing or sample, and our team will help you unlock the best fit for your industrial setup.Q: What surface finish options are available for these shrouds?

A: You can redeem finishes such as galvanized, painted, metallic grey, shot blasted, or sand blasted. Surface treatment is configurable based on process requirements or specific client requests.Q: When should I replace or upgrade my relief valve shroud?

A: Replace your shroud if you notice any signs of wear, corrosion, or after a scheduled maintenance interval. Upgrading to our lustrous, corrosion-resistant design ensures enhanced protection and reliability.Q: Where are your Relief Valve Casting Shrouds manufactured and supplied from?

A: All our shrouds are manufactured and supplied from our advanced facility in India, adhering to ASTM, ANSI, and IS standards, supported by quality OEM manufacturing.Q: What is the process for quality testing your shrouds?

A: Every Relief Valve Casting Shroud undergoes 100% hydrostatic and visual inspection, unlocking confidence in safety, dimensional accuracy, and radiant performance.Q: What are the main benefits of using this product in industrial environments?

A: Our shrouds offer ravishing protection for relief valves against harsh conditions, ensuring operational safety, high pressure endurance, and reduced maintenance with their corrosion-resistant, precision-manufactured construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tractor Parts (Massey Ferguson) Category

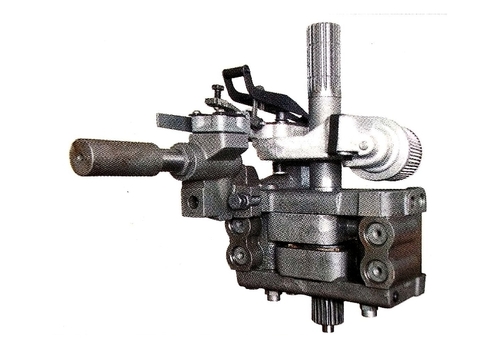

HYD Lift Pump Assly With Pressure Control Unit Mark III (21 Splines)

Minimum Order Quantity : 5000 Pieces

Weight : 6.7 kg (approx)

Type : Hydraulic Lift Pump Assembly with Pressure Control Unit, Mark III

Material Capabilities : High tensile strength, corrosion resistance, and hydraulic fluid compatibility

Standard : OEM equivalent, conforming to tractor industry standards

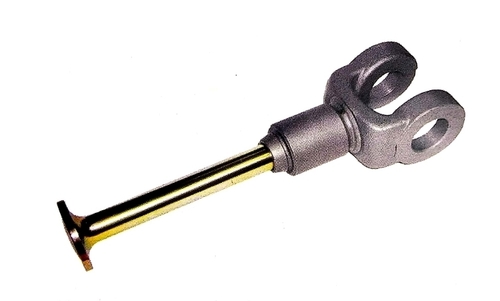

HYD Lift Clevis With Plunger

Minimum Order Quantity : 100 Pieces

Weight : Approx. 1.25 Kg

Type : Lift Clevis With Plunger

Material Capabilities : High Tensile Strength, Corrosion Resistance

Standard : IS, DIN Standards

Rear Axle Hub

Minimum Order Quantity : 100 Pieces

Weight : 3 9 kg (depending on application)

Type : Rear Axle Hub

Material Capabilities : Hightensile strength, corrosion resistance

Standard : OEM/ISO 9001:2015 Compliant

Ram Cylinder Piston Ring 93mm

Minimum Order Quantity : 100 Pieces

Weight : Approx. 200250 grams

Type : Ram Cylinder Piston Ring

Material Capabilities : WearResistant, High Strength

Standard : OEM Standard

GST : 24ACMPP1179R1ZT

|

JAY SHAKTI ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry