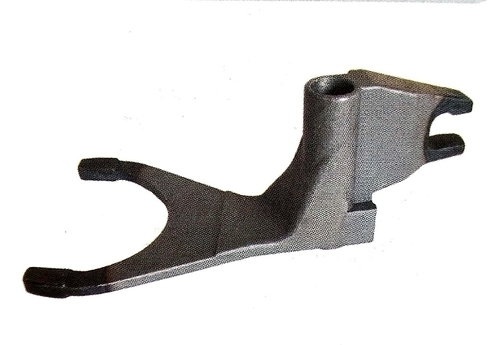

HYD Lift Position Control Fork

HYD Lift Position Control Fork Specification

- Weight

- 2.7 kg

- Type

- Lift Position Control Fork

- Material

- Alloy Steel

- Drawing

- Available on Request

- Finish

- Black Oxide Coated

- Standard

- IS 5517:1993

- Material Capabilities

- High Tensile Strength, Corrosion Resistant

- Micro Machining

- No

- Tolerance

- 0.05 mm

- Surface Treatment

- Heat Treated

- Hardness

- 38-42 HRC

- Application

- Hydraulic Lifts, Tractor Implements

- Packaging Type

- Wooden Box or as per requirement

- Shape

- Forked

- OEM Service

- Provided

- Feature

- Robust Design, Dimensional Accuracy

HYD Lift Position Control Fork Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 20 Days

About HYD Lift Position Control Fork

Outstanding Features and Versatile Applications

The HYD Lift Position Control Fork stands out with its robust design, black oxide coating, and high dimensional precision. Suitable for a range of industrial machines and plant equipment, it withstands heavy-duty use due to its high tensile strength and corrosion resistance. Engineered for reliability, it easily integrates into hydraulic lifts and tractor implements, optimizing machinery performance. This fork is heat treated to ensure long-lasting functionality, making it an ideal choice for demanding applications across industrial sectors.

Secure Packaging, Flexible Payment & Global Delivery

Each HYD Lift Position Control Fork is securely handed over in a wooden box or customised packaging upon request, ensuring safe delivery. Quotations and estimates are promptly provided for both bulk and individual orders. Payment terms are tailored for convenience, including options for advance or on-delivery. Our export reach spans major international markets, delivering consistent quality worldwide. From your first enquiry to product hand-off, our streamlined process prioritizes efficiency and customer satisfaction.

FAQs of HYD Lift Position Control Fork:

Q: How can I personalise the HYD Lift Position Control Fork for my specific requirements?

A: You can personalise the fork by specifying your packaging preferences, requesting custom drawings, or providing OEM requirements during your inquiry. Our team assists in tailoring the fork to your unique needs.Q: What makes the HYD Lift Position Control Fork unbeatable in performance?

A: Its unbeatable performance stems from its high-tensile strength alloy steel construction, heat treatment, and immaculate dimensional accuracy. These features ensure exceptional durability and reliable operation in demanding environments.Q: Where is the HYD Lift Position Control Fork commonly used?

A: This fork is predominantly used in hydraulic lifts and tractor implements, but its robust build also suits various types of industrial machinery and plant operations.Q: What is the process to receive a quotation or estimate for this product?

A: Simply contact us with your requirements, and we will promptly provide a detailed quotation or estimate. Drawing assistance and technical support are also available upon request.Q: What are the main benefits of using the HYD Lift Position Control Fork?

A: Using this fork provides benefits such as unmatched corrosion resistance, strength under heavy loads, precise control, and long-lasting performance, ensuring optimal machine efficiency and reduced maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tractor Parts (Massey Ferguson) Category

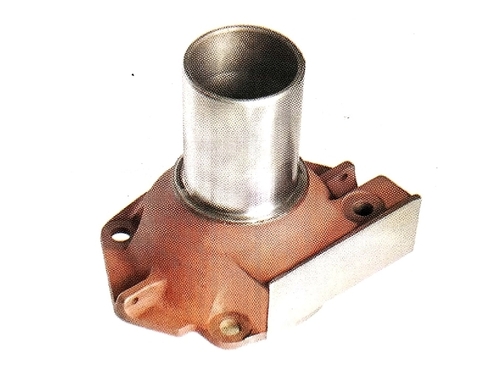

Gear Box Input Housing Multi Power Retainer

Minimum Order Quantity : 100 Pieces

Standard : OEM/Industry Standard

Material Capabilities : High strength, Wear resistance

Tolerance : 0.05 mm

Weight : 7.5 kg

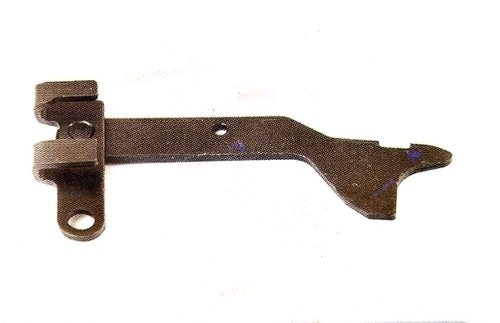

HYD Cam Assy (Hydraulic Leakage Lever)

Minimum Order Quantity : 100 Pieces

Standard : OEM/Industry Standard

Material Capabilities : High tensile strength, corrosion resistance

Tolerance : 0.02 mm

Weight : Approx. 450g

HYD Lift Arm Shaft (Three Hole) 37 Splines

Minimum Order Quantity : 100 Pieces

Standard : OEM/Replacement Quality

Material Capabilities : High Strength, Wear Resistant

Tolerance : 0.01 mm

Weight : Approx. 4.5 kg

Gear Fork Big

Minimum Order Quantity : 100 Pieces

Standard : OEM/Customized

Material Capabilities : High Tensile Strength, Wear Resistance

Tolerance : 0.02 mm

Weight : Approx 400600 grams

GST : 24ACMPP1179R1ZT

|

JAY SHAKTI ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry