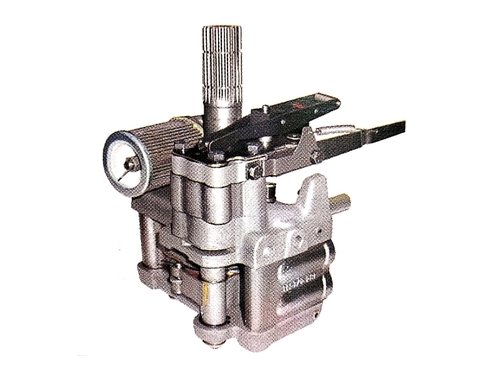

Plunger Yoke O-M

Plunger Yoke O-M Specification

- Material

- O-M (Oxygen-Mild steel)

- Material Capabilities

- High strength, corrosion resistance

- Standard

- OEM or as per customer drawing

- Type

- Plunger Yoke

- Drawing

- Customized or standard available

- Finish

- Smooth machined finish, rust preventive coating

- Micro Machining

- Available upon request

- Tolerance

- 0.05 mm

- Weight

- Approx. 500 g 1.5 kg

Plunger Yoke O-M Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 20 Days

About Plunger Yoke O-M

High-Performance for Diverse Plant Applications

The Plunger Yoke O-M excels in plant environments where reliability in motion transfer is paramount. Designed for both automotive and industrial machinery, it features a carburized, tempered surface and robust phosphating. Its O-M steel composition grants durability and resistance to corrosion, while the smooth machined finish minimizes wear. Outstanding tolerance and micro machining options ensure perfect fit for OEM or custom designs, making it a key element in demanding plant operations.

Export Market Leadership & Sample Policy

With eminent presence in key export markets, the Plunger Yoke O-M caters to global demand with swift drop-off and secure export-quality packaging. Interested buyers can request samplesour policy provides them at a favorable proposal amount, with detailed quotations to support procurement decisions. The streamlined sample process ensures that potential clients obtain firsthand experience of product excellence before placing bulk orders, reinforcing trust and satisfaction in our offerings.

FAQs of Plunger Yoke O-M:

Q: How is the Plunger Yoke O-M manufactured for consistent quality?

A: The Plunger Yoke O-M is manufactured through advanced CNC machining and lathe turning, ensuring precise dimensions and smooth finishes. This process guarantees high strength, close tolerance, and repeatable quality for every unit produced.Q: What surface treatments are available for the Plunger Yoke O-M?

A: Surface treatments include phosphating for corrosion resistance or other custom options as required by the client. Each plunger yoke also receives a rust-preventive coating for enhanced longevity in challenging environments.Q: When can samples of the Plunger Yoke O-M be requested, and what is the policy?

A: Samples can be requested at any stage of the proposal process. We offer samples upon a predetermined proposal amount, detailed in our quotation, giving clients the opportunity to evaluate before committing to larger orders.Q: Where can the Plunger Yoke O-M be used most effectively?

A: The Plunger Yoke O-M is suitable for a range of applications in both automotive assemblies and industrial machinery, especially where robust mechanical performance and corrosion resistance are crucial.Q: What benefits are offered by choosing an OEM or custom Plunger Yoke O-M?

A: Choosing an OEM or custom Plunger Yoke O-M guarantees compatibility with your specific equipment, ensures rapid integration into your assemblies, and allows customization of features like threading, heat treatment, and finish for unique operational demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tractor Parts (Ford) Category

Plunger Yoke N-M

Minimum Order Quantity : 100 Pieces

Finish : Polished

Type : Plunger Yoke NM

Drawing : Available on Request

Standard : DIN 71802

Stand Pipe

Minimum Order Quantity : 100 Pieces

Finish : Polished / Matt / Electroplated

Type : Stand Pipe

Drawing : Custom Drawings Accepted

Standard : ASTM/ASME A/SA213, A269, DIN, JIS, EN

HYD Lift Pump Assly MF-245 (21 Splines)

Minimum Order Quantity : 5000 Pieces

Finish : Precision Machined with AntiCorrosive Coating

Type : Hydraulic Lift Pump Assembly

Drawing : Available upon request

Standard : OEM Standard for MF245 Tractors

Flow Control Valve Assly Ford 3610 STD

Minimum Order Quantity : 100 Pieces

Finish : Corrosionresistant Coating

Type : Flow Control Valve Assembly

Drawing : Available On Request

Standard : Ford 3610 STD

GST : 24ACMPP1179R1ZT

|

JAY SHAKTI ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry